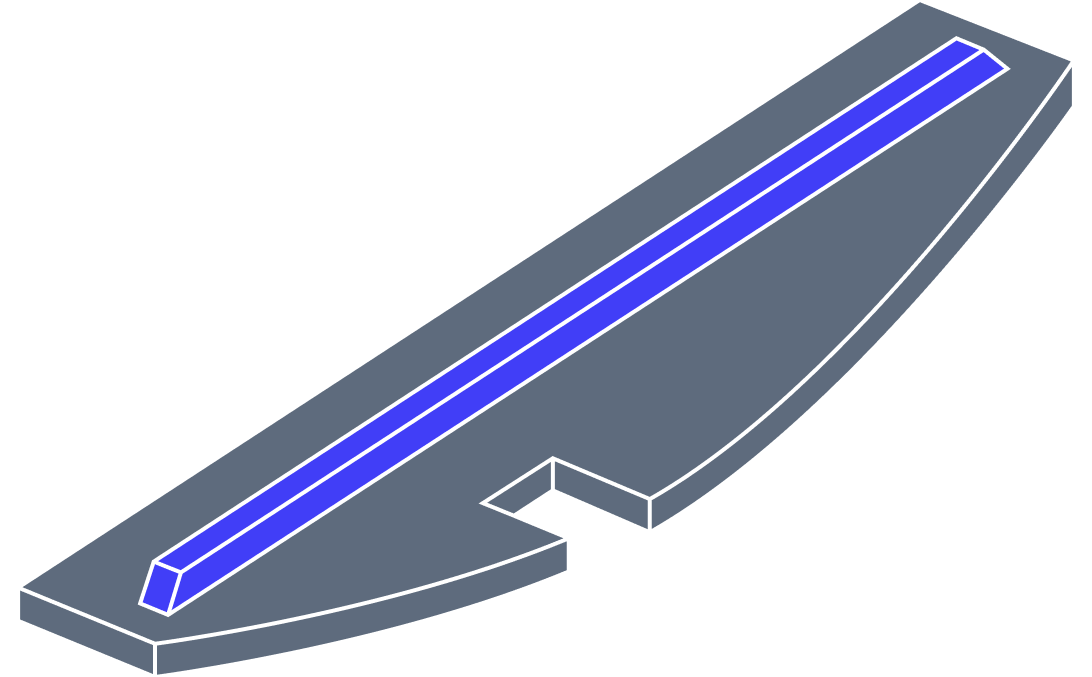

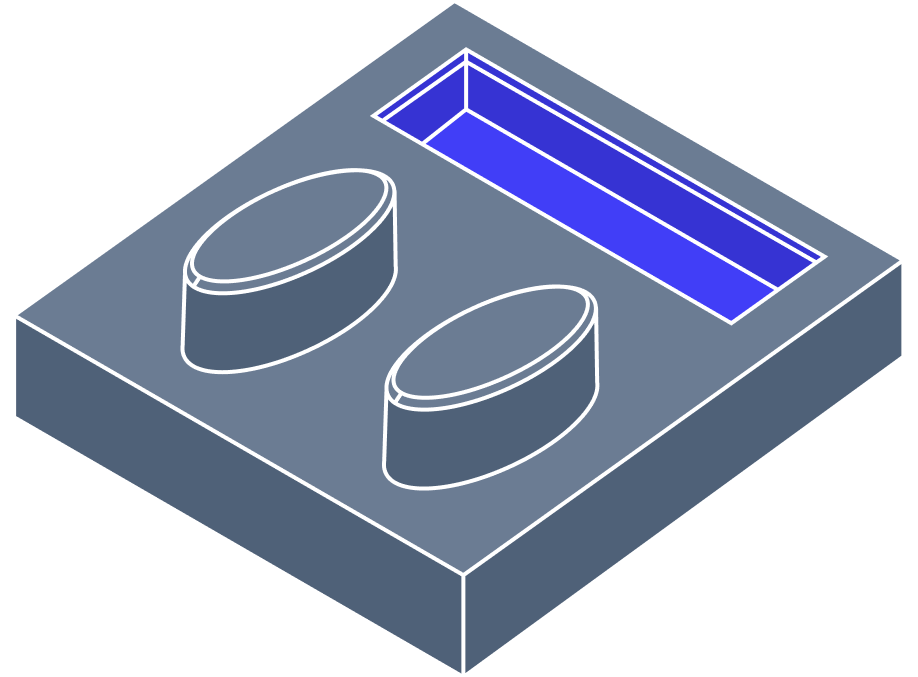

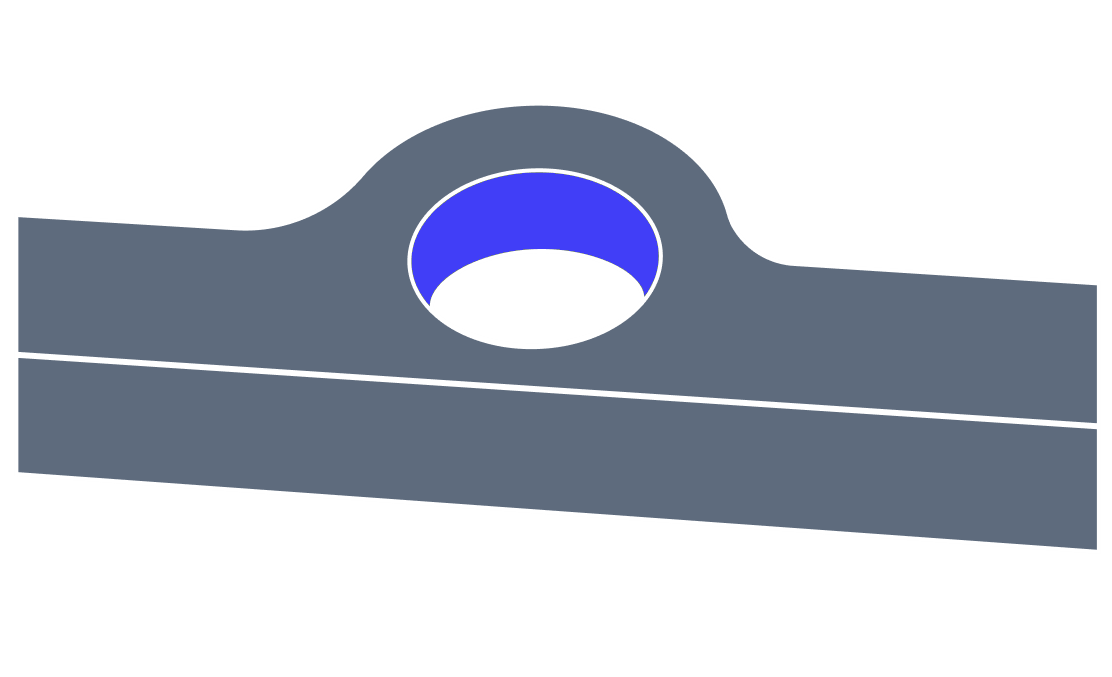

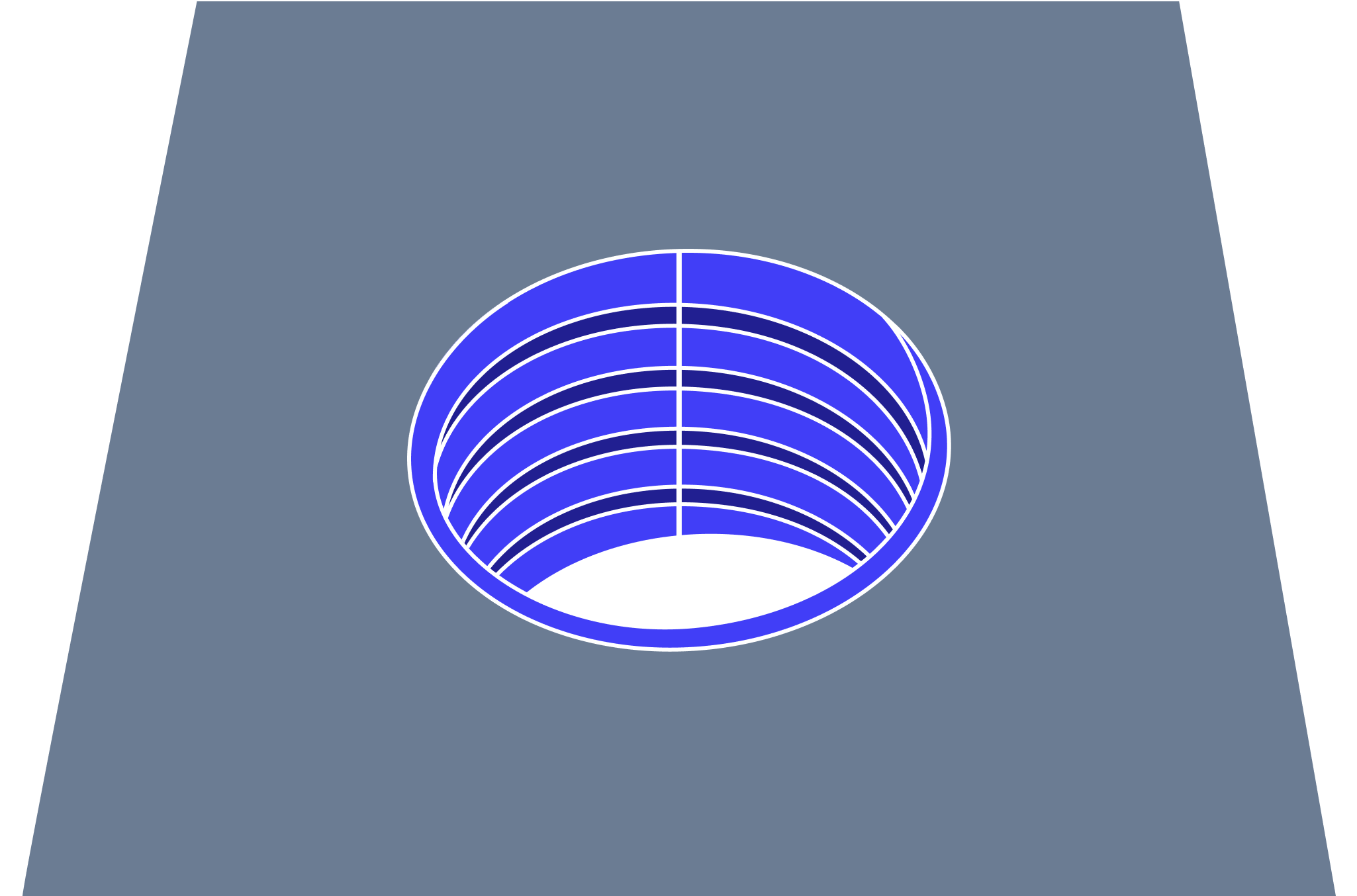

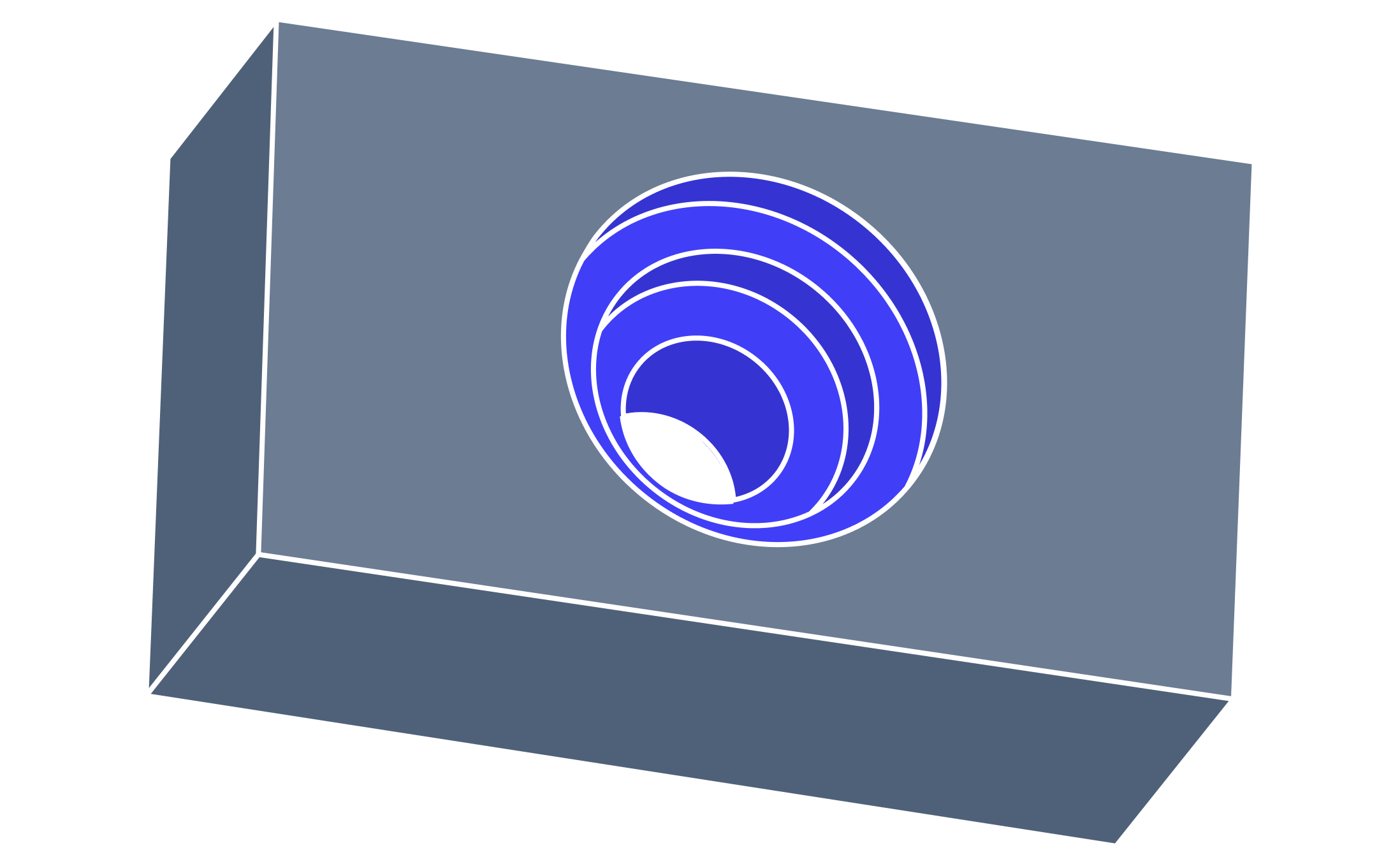

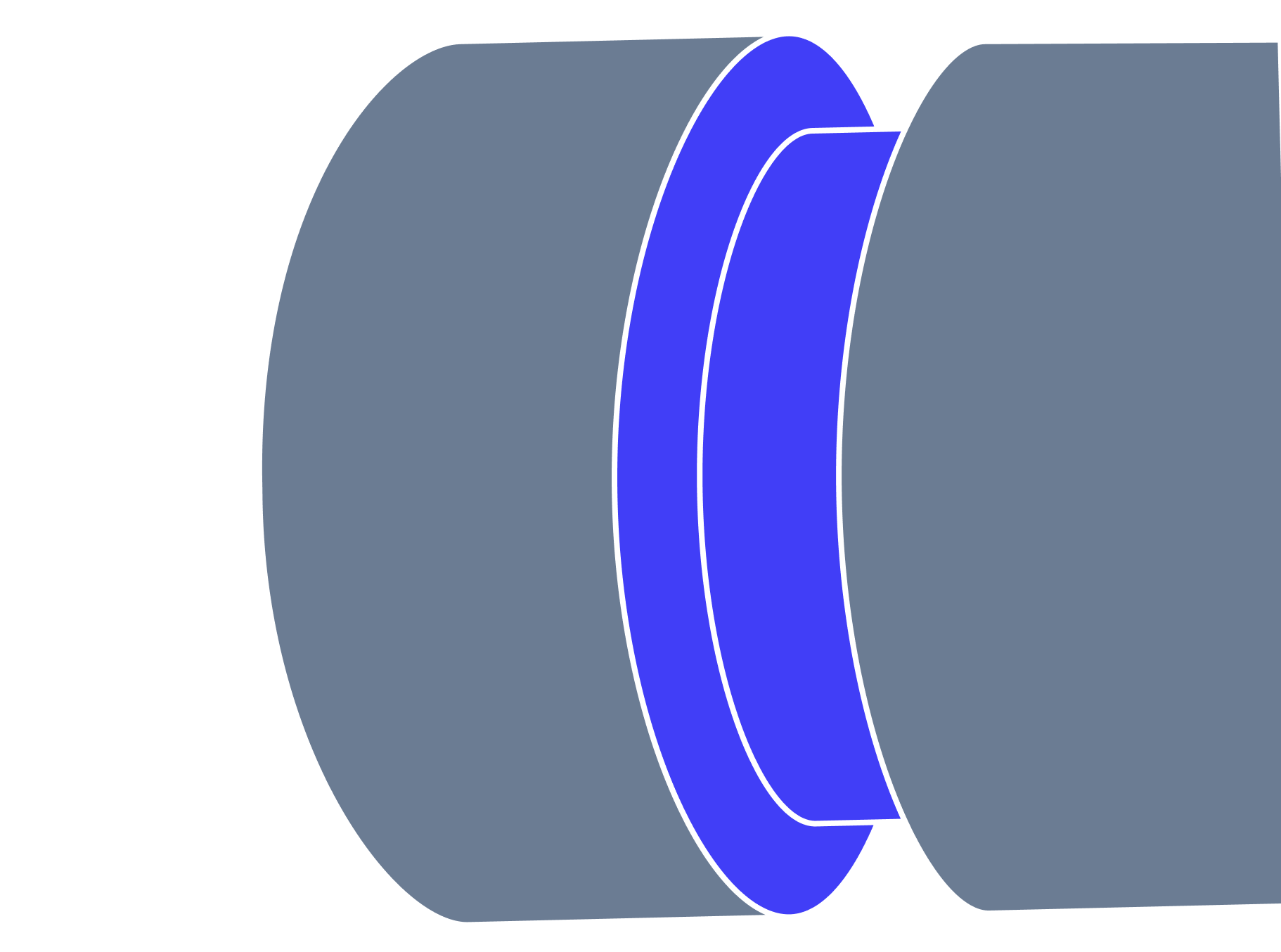

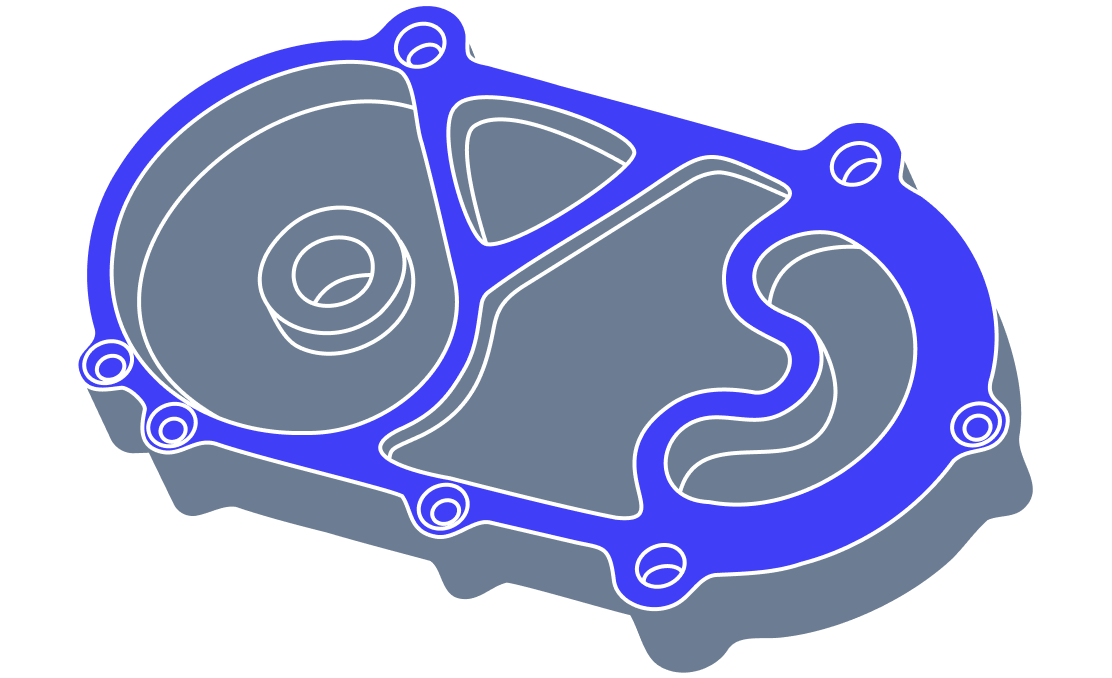

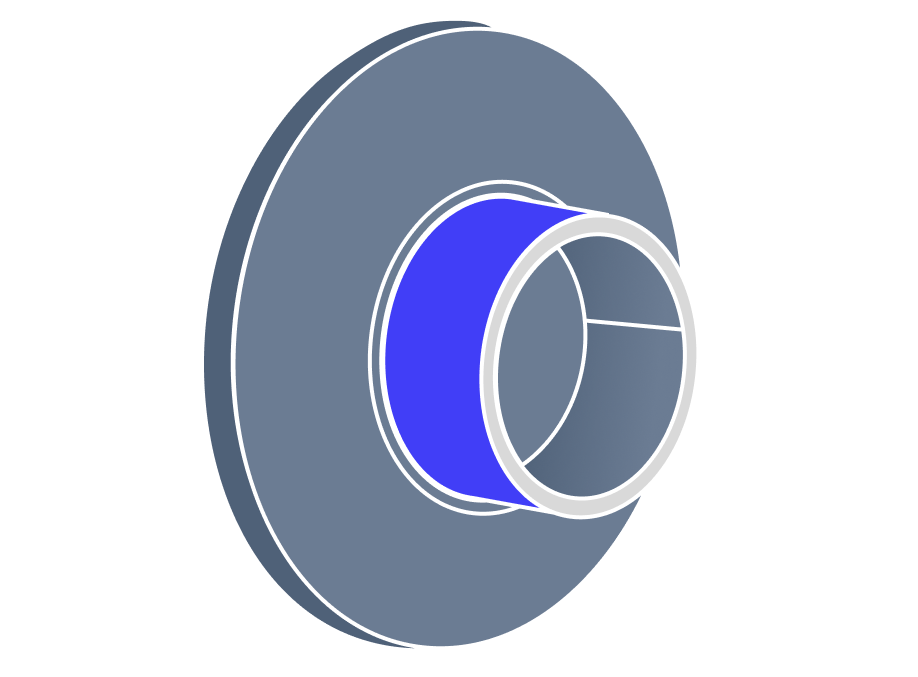

| Type | Description | Example of visual representation |

| MTKBase_Boss | A boss is a protrusion or raised area on a workpiece that is created by removing material around it using a milling cutter. The boss feature can be used for various purposes such as providing a location for fasteners, creating a bearing surface, or serving as a mounting point for other components. |

|

| Machining_Pocket | A pocket is a feature obtained by milling the material inside an arbitrarily closed boundary on a flat surface of a workpiece removed to a fixed depth. |

|

| Machining_Hole | Hole is a cylindrical feature that can be made by cutting from the workpiece by a rotating cutting tool. The hole can be either a through hole or a blind hole. A through hole is a complete hole that you can see on both sides of the object, while a blind hole is only drilled, milled or reamed to get a specific depth. The blind hole can have a flat bottom or pointed end due to the ending point of the tool. Also, holes can be made at the edge of the material – partial holes, in this case only part of the hole is in the material. |

|

| Machining_ThreadedHole | A threaded hole is a cylindrical hole with a helical thread (groove) machined on its inner surface. The helical thread is designed to fit with the corresponding external threaded components, such as screws, bolts, and studs, providing for secure fastening and reliable mechanical connections. |

|

| Machining_Countersink | A conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material. |

|

| Machining_SteppedHole | Stepped Hole is a machined hole with two or more sections of different diameters, aligned along the same axis. It combines simple holes and countersinks into a single feature, typically created through drilling, counterboring, and countersinking operations. |

|

| Machining_TurningGroove | A turning groove is a narrow linear channel or cut made in a material using a lathe machine. The groove type depends on the position where groove is machined. |

|

| Machining_Face or Machining_TurningFace | A face is a feature produced by a milling or turning operation. The face type is associated with the process in which the face was machined. |

|