Sheet metal product designs start with CAD files and in order to get the manufacturable sheet metal parts. Those CAD files should follow specific sheet metal design guidelines. Using a Design for Manufacturing (DFM) strategy decreases possible issues in sheet metal design from the beginning, saving both time and money.

The DFM analysis for Sheet Metal can be run on a CAD file in order to find any possible design issues, e.g. small distance between holes, inconsistent bend radii, etc. As a result of the analysis, features of the part that don't meet the DFM check criteria will be found.

As the API changes to accommodate the needs of users compatibility will be preserved as much as possible but is ultimately not guaranteed.

The DFM analysis can reveal various possible design issues in a sheet metal part, the full list of them is listed here.

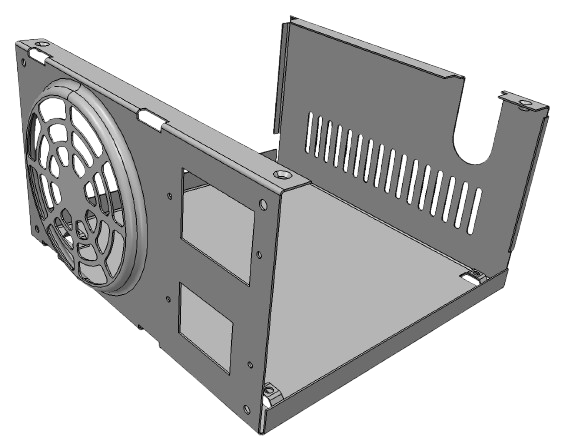

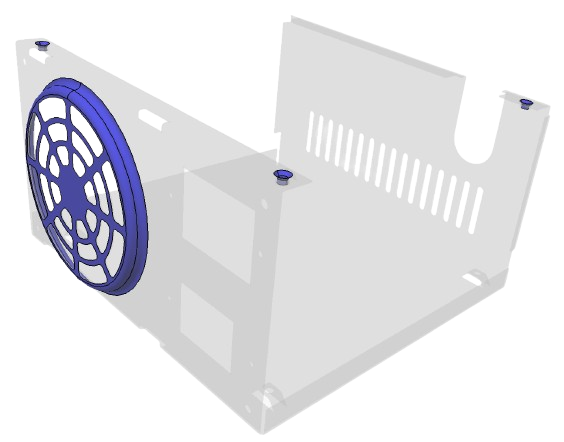

Below is a simple example of DFM analysis.

| 3D model | Issues |

|---|---|

|

|

The DFM analysis can be done on B-Rep representations, namely it works with ModelData::Shell or ModelData::Solid .

DFMSheetMetal_Analyzer is the class that performs sheet metal DFM analysis. It has parameters that allow to modify rules for analysis. There are 2 ways to perform DFM analysis:

DFMSheetMetal_Analyzer is sensitive to the models' thickness. In order to get acceptable results, use a model with constant thickness. Otherwise, results can be inaccurate.