Describes large turned part issue found during cnc machining turning design analysis. More...

Public Member Functions | |

| DFMMachining_LargeTurnedPartIssue () | |

| Constructor. | |

| const DFMMachining_TurnedPartSize & | ExpectedMaxTurnedPartSize () const |

| Returns the expected maximum turned part size. | |

| void | SetExpectedMaxTurnedPartSize (const DFMMachining_TurnedPartSize &theTurnedPartSize) |

| Sets expected maximum turned part size. | |

| const DFMMachining_TurnedPartSize & | ActualTurnedPartSize () const |

| Returns the actual turned part size. | |

| void | SetActualTurnedPartSize (const DFMMachining_TurnedPartSize &theTurnedPartSize) |

| Sets actual turned part size. | |

Public Member Functions inherited from cadex::MTKBase_Feature Public Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature () | |

| Constructor. | |

| ~MTKBase_Feature () | |

| Destructor. | |

| void | Nullify () |

| Resets reference to implementation object. | |

| bool | IsNull () const |

| Returns true if the object is nullified. | |

| operator bool () const | |

| Casts the object to the bool type. | |

| template<typename T > | |

| bool | IsOfType () const |

| ImplType * | Impl () const |

| template<typename T > | |

| T * | Impl () const |

| Reserved for internal use. | |

| bool | operator== (const MTKBase_Feature &theObject) const |

| bool | operator!= (const MTKBase_Feature &theObject) const |

Static Public Member Functions | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returns true if theFeature is a DFM machining large turned part issue. | |

Static Public Member Functions inherited from cadex::DFMBase_Issue Static Public Member Functions inherited from cadex::DFMBase_Issue | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returnstrue if theFeature is a DFM issue. | |

Additional Inherited Members | |

Public Types inherited from cadex::DFMBase_Issue Public Types inherited from cadex::DFMBase_Issue | |

| typedef cadex::internal::DFMBaseImpl_Issue | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Public Types inherited from cadex::MTKBase_Feature Public Types inherited from cadex::MTKBase_Feature | |

| typedef cadex::internal::MTKBaseImpl_Feature | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Protected Member Functions inherited from cadex::DFMBase_Issue Protected Member Functions inherited from cadex::DFMBase_Issue | |

| DFMBase_Issue (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Member Functions inherited from cadex::MTKBase_Feature Protected Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Attributes inherited from cadex::MTKBase_Feature Protected Attributes inherited from cadex::MTKBase_Feature | |

| ImplPtrType | myImpl |

Describes large turned part issue found during cnc machining turning design analysis.

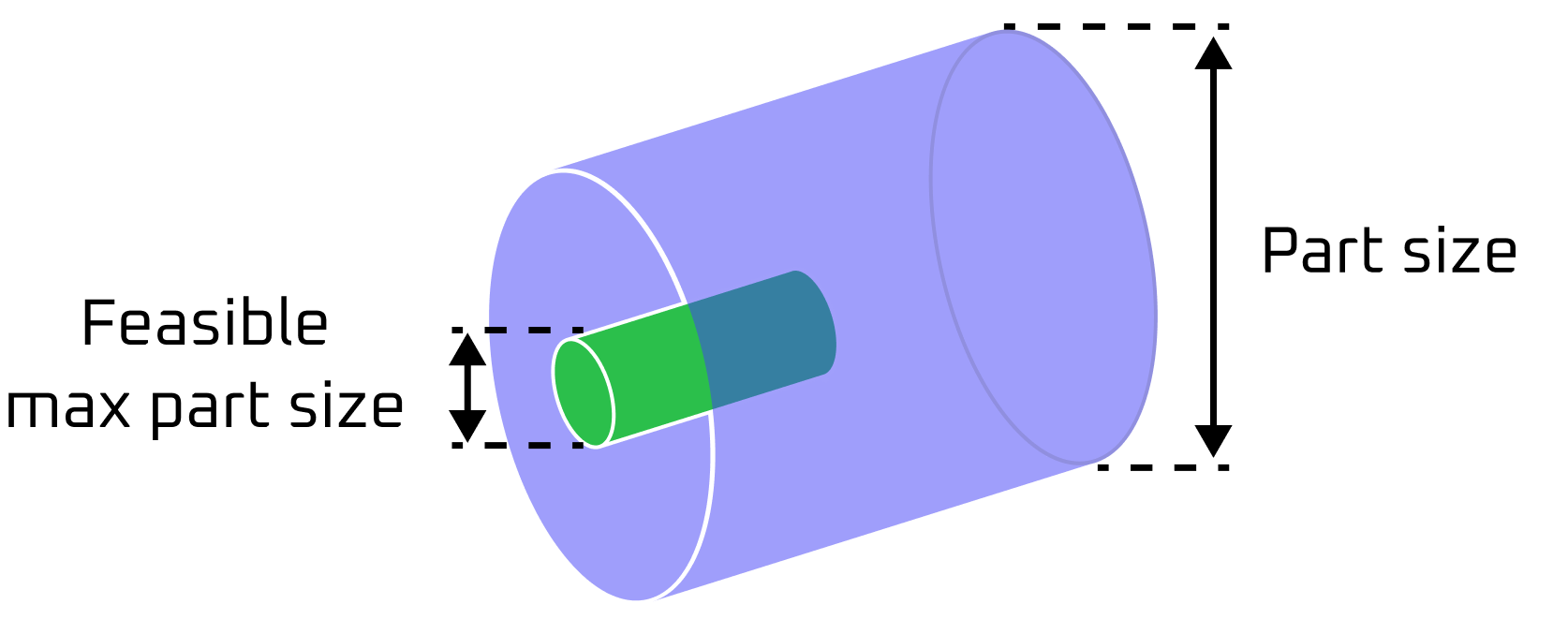

A large turned part issue in cnc machining turning design refers to the difficulties faced in producing oversized components in a turning operation. These parts require specialized equipment and expertise, as well as careful consideration of factors such as stability, tool selection, and programming. Some common challenges include maintaining consistency of material removal, ensuring proper chip evacuation, and minimizing vibration and deflection.

Contains turned part size that fails the following condition:

\[ \large L_p \leq l_m \quad \text{and} \quad R_p \leq r_m \]

\[ \begin{aligned} & \small L_p - \text{actual turned part length} \\ & \small R_p - \text{actual turned part radius} \\ & \small l_m - \text{expected maximum turned part length} \\ & \small r_m - \text{expected maximum turned part radius} \end{aligned} \]

| cadex::DFMMachining_LargeTurnedPartIssue::DFMMachining_LargeTurnedPartIssue | ( | ) |

Constructor.

| const DFMMachining_TurnedPartSize & cadex::DFMMachining_LargeTurnedPartIssue::ActualTurnedPartSize | ( | ) | const |

Returns the actual turned part size.

|

static |

Returns true if theFeature is a DFM machining large turned part issue.

| const DFMMachining_TurnedPartSize & cadex::DFMMachining_LargeTurnedPartIssue::ExpectedMaxTurnedPartSize | ( | ) | const |

Returns the expected maximum turned part size.

| void cadex::DFMMachining_LargeTurnedPartIssue::SetActualTurnedPartSize | ( | const DFMMachining_TurnedPartSize & | theTurnedPartSize | ) |

Sets actual turned part size.

| void cadex::DFMMachining_LargeTurnedPartIssue::SetExpectedMaxTurnedPartSize | ( | const DFMMachining_TurnedPartSize & | theTurnedPartSize | ) |

Sets expected maximum turned part size.