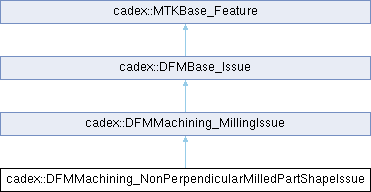

Describes non perpendicular milled part shape issue found during cnc machining milling design analysis. More...

Public Member Functions | |

| DFMMachining_NonPerpendicularMilledPartShapeIssue () | |

| Constructor. | |

| double | ActualAngle () const |

| void | SetActualAngle (double theAngle) |

| const ModelData::Shell & | Shape () const |

| void | SetShape (const ModelData::Shell &theShell) |

Public Member Functions inherited from cadex::MTKBase_Feature Public Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature () | |

| Constructor. | |

| ~MTKBase_Feature () | |

| Destructor. | |

| void | Nullify () |

| bool | IsNull () const |

| operator bool () const | |

| Casts the object to the bool type. | |

| template<typename T > | |

| bool | IsOfType () const |

| ImplType * | Impl () const |

| template<typename T > | |

| T * | Impl () const |

| Reserved for internal use. | |

| bool | operator== (const MTKBase_Feature &theObject) const |

| bool | operator!= (const MTKBase_Feature &theObject) const |

Static Public Member Functions | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returns true if theFeature is a DFM machining non perpendicular milled part shape issue. | |

Static Public Member Functions inherited from cadex::DFMMachining_MillingIssue Static Public Member Functions inherited from cadex::DFMMachining_MillingIssue | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returns true if theIssue is a DFM machining milling issue. | |

Static Public Member Functions inherited from cadex::DFMBase_Issue Static Public Member Functions inherited from cadex::DFMBase_Issue | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returnstrue if theFeature is a DFM issue. | |

Additional Inherited Members | |

Public Types inherited from cadex::DFMMachining_MillingIssue Public Types inherited from cadex::DFMMachining_MillingIssue | |

| typedef cadex::internal::DFMMachiningImpl_MillingIssue | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Public Types inherited from cadex::DFMBase_Issue Public Types inherited from cadex::DFMBase_Issue | |

| typedef cadex::internal::DFMBaseImpl_Issue | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Public Types inherited from cadex::MTKBase_Feature Public Types inherited from cadex::MTKBase_Feature | |

| typedef cadex::internal::MTKBaseImpl_Feature | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Protected Member Functions inherited from cadex::DFMMachining_MillingIssue Protected Member Functions inherited from cadex::DFMMachining_MillingIssue | |

| DFMMachining_MillingIssue (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Member Functions inherited from cadex::DFMBase_Issue Protected Member Functions inherited from cadex::DFMBase_Issue | |

| DFMBase_Issue (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Member Functions inherited from cadex::MTKBase_Feature Protected Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Attributes inherited from cadex::MTKBase_Feature Protected Attributes inherited from cadex::MTKBase_Feature | |

| ImplPtrType | myImpl |

Describes non perpendicular milled part shape issue found during cnc machining milling design analysis.

In cnc milling, non perpendicular shape refers to side and bottom surfaces that separated by a floor fillet and are not perpendicular to each other. When surfaces are separated by a floor fillet, the stress concentration increases at that point. When these surfaces are not perpendicular to each other, the stress concentration may be further exacerbated. Moreover, machining two surfaces that are not perpendicular to each other requires positioning the tool at an oblique angle, leading to increased tool wear and reduced tool life. Additionally, the uneven surface requires more machining time and requires specialized tooling and techniques.

| double cadex::DFMMachining_NonPerpendicularMilledPartShapeIssue::ActualAngle | ( | ) | const |

Returns the actual milled part shape angle in radians .

| void cadex::DFMMachining_NonPerpendicularMilledPartShapeIssue::SetActualAngle | ( | double | theAngle | ) |

Sets actual milled part shape angle in radians . theAngle should be greater or equal to zero.

| void cadex::DFMMachining_NonPerpendicularMilledPartShapeIssue::SetShape | ( | const ModelData::Shell & | theShape | ) |

Sets the problematic shape.

| const ModelData::Shell & cadex::DFMMachining_NonPerpendicularMilledPartShapeIssue::Shape | ( | ) | const |

Returns the problematic shape.