CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece. It involves the use of computer-aided design (CAD) software to create a 3D model of the desired part or component, which is then translated into instructions for the CNC machine. The CNC machine follows these instructions to precisely cut, shape, drill, and finish the workpiece according to the design specifications. It can perform a wide range of operations such as milling, turning, drilling, and grinding with high accuracy and repeatability.

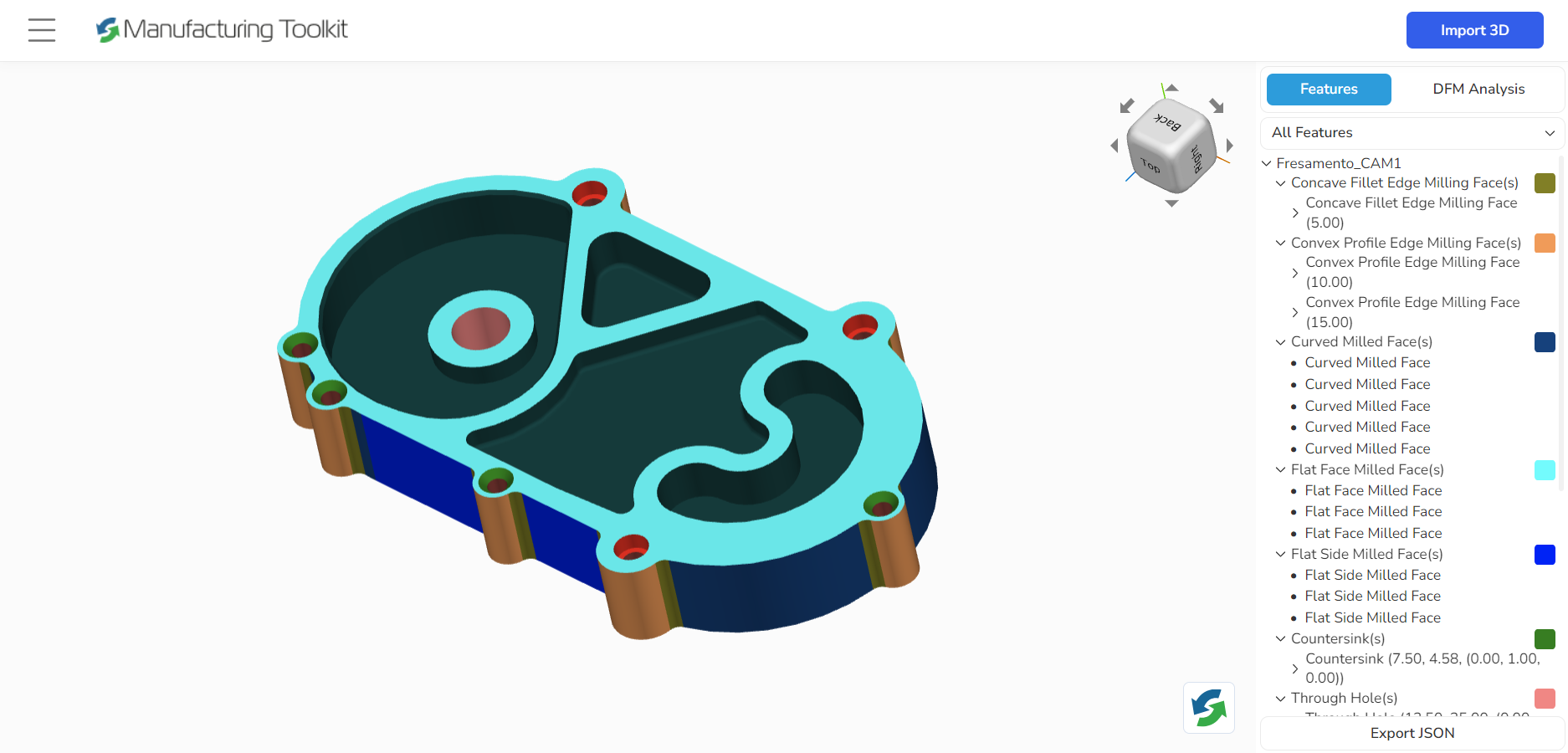

Manufacturing Toolkit contains tools that allow to recognize machining features produced by CNC Machining processes (Milling/Drilling/Turning) and analyze them for possible design issues. However, models that are passed to the Manufacturing Toolkit should meet a certain requirements:

A detailed overview of these tools is covered in a separate topics:

To get a quick feeling of what can be achieved with the help of these tools, please try our web demo.

|