The recognition can be run on a CAD file to find machining features, e.g. pockets, holes, etc. As a result of the recognition, list of found features of the part will be returned.

As the API changes to accommodate the needs of users compatibility will be preserved as much as possible but is ultimately not guaranteed.

It is possible to recognize pockets, holes of various types (through, blind, flat-bottom, partial), countersinks and milling/turning faces. A detailed description of the features is given here.

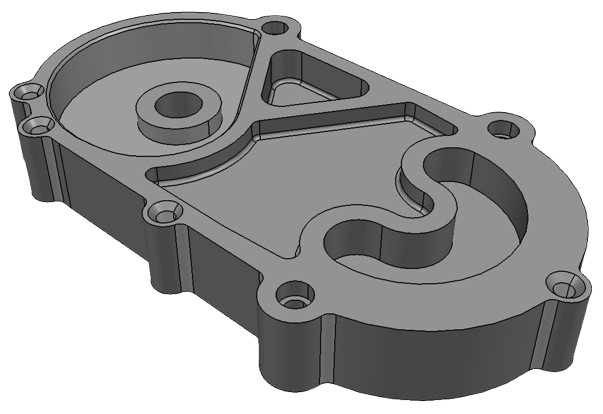

Below is a simple example of recognition.

| CNC Machining model | Features |

|---|---|

|

The recognition can be run on B-Rep representations, namely it works with ModelData::Solid .

Machining_FeatureRecognizer is the class that performs machining feature recognition. The tool has parameters that allow to modify rules for recognition.

There are 2 possible ways to use machining tools:

The resulting Machining_Data can be passed as an input parameter for tools. Machining_Data can be used to run machining tools separately.