Sheet metal is a manufacturing process of forming and shaping thin metal sheets into desired shapes and sizes. It involves various techniques such as cutting, bending, punching, and welding to transform flat metal sheets into finished products. In addition to these basic steps, sheet metal process can also involve other techniques such as deep drawing, forming, embossing, or hydroforming, depending on the specific requirements of the product being manufactured. These additional techniques allow for further customization and the creation of more complex shapes and features.

Manufacturing Toolkit contains tools that allow to recognize features produced by Sheet Metal process and analyze them for possible design issues, unfold an original sheet metal model and create a drawing. However, models that are passed to the Manufacturing Toolkit should meet a certain requirements:

A detailed overview of these tools is covered in a separate topics:

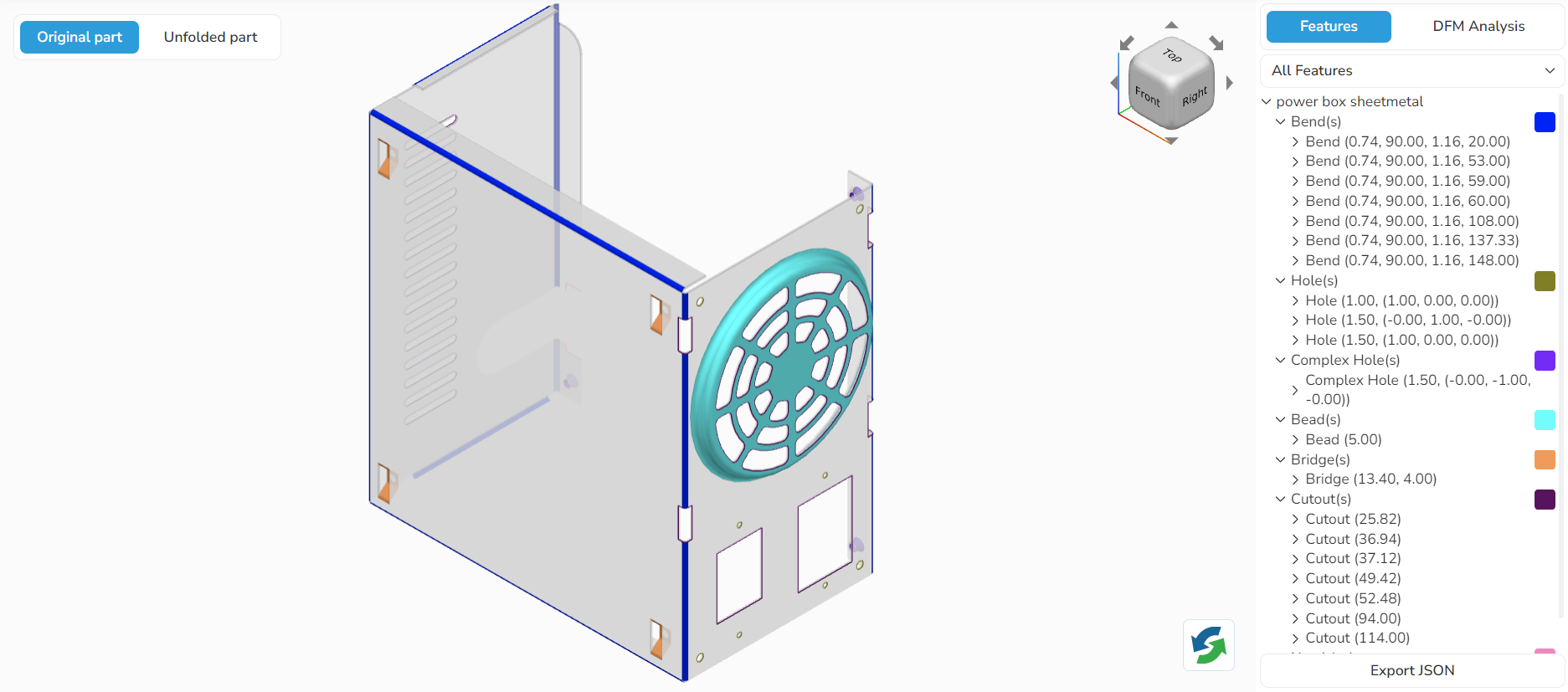

To get a quick feeling of what can be achieved with the help of these tools, please try our web demo.

|