The recognition can be run on a CAD file to find sheet metal features, e.g. bends, beads, holes, cutouts, etc. As a result of the recognition, list of found features of the part will be returned.

As the API changes to accommodate the needs of users compatibility will be preserved as much as possible but is ultimately not guaranteed.

It is possible to recognize bends of various types (simple, curved, hem or compound), beads, bridges, louvers, cutouts, holes, tabs and notches. A detailed description of the features is given here.

Below is a simple example of recognition.

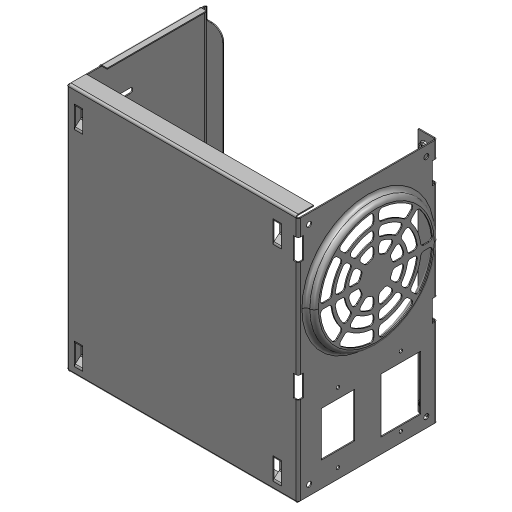

| Sheet Metal model | Features |

|---|---|

|

The recognition can be run on B-Rep representations, namely it works with ModelData::Shell or ModelData::Solid .

SheetMetal_FeatureRecognizer is the class that performs sheet metal feature recognition.

There are 2 ways to perform recognition:

The resulting SheetMetal_Data can be passed as an input parameter for tools. But make sure to not using empty SheetMetal_Data. Simply run SheetMetal_Analyzer without adding any tool to get minimum required SheetMetal_Data. It can be used to get thickness and / or to run sheet metal tools separately with SheetMetal_Data.

Sheet Metal tools are sensitive to the models' thickness. In order to get acceptable results, use a model with constant thickness. Otherwise, results can be inaccurate.