Describes small length flange issues found during sheet metal design analysis. More...

Public Member Functions | |

| DFMSheetMetal_SmallLengthFlangeIssue () | |

| Constructor. | |

| DFMSheetMetal_SmallLengthFlangeIssue (const MTKBase_CompositeFeature &theFlange) | |

| Constructor. | |

| const MTKBase_CompositeFeature & | Flange () const |

| Returns the problematic flange. | |

| void | SetFlange (const MTKBase_CompositeFeature &theFlange) |

| Sets the problematic flange The first feature in MTKBase_CompositeFeature should be the flange bend (SheetMetal_Bend) and the second is an end flage face (ModelData::Face) as MTKBase_ShapeFeature object. | |

| double | ExpectedMinLengthToSheetThicknessRatio () const |

| Returns the expected minimum flange length to thickness ratio. | |

| void | SetExpectedMinLengthToSheetThicknessRatio (double theRatio) |

| Sets the expected minimum flange length to thickness ratio. | |

| double | ExpectedMinLength () const |

| Returns the expected minimum flange length in mm . | |

| double | ActualLength () const |

| Returns the actual flange length in mm . | |

| void | SetActualLength (double theLength) const |

| Sets the actual flange length in mm. | |

Public Member Functions inherited from cadex::DFMSheetMetal_BendIssue Public Member Functions inherited from cadex::DFMSheetMetal_BendIssue | |

| const SheetMetal_Bend & | Bend () const |

| Returns the problematic sheet metal bend. | |

| void | SetBend (const SheetMetal_Bend &theBend) |

| Sets the problematic sheet metal bend. | |

| double | ActualSheetThickness () const |

| Returns the actual sheet thickness of analyzed part in mm . | |

| void | SetActualSheetThickness (double theThickness) |

| Sets the actual sheet thickness in mm . | |

Public Member Functions inherited from cadex::MTKBase_Feature Public Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature () | |

| Constructor. | |

| ~MTKBase_Feature () | |

| Destructor. | |

| void | Nullify () |

| Resets reference to implementation object. | |

| bool | IsNull () const |

| Returns true if the object is nullified. | |

| operator bool () const | |

| Casts the object to the bool type. | |

| template<typename T > | |

| bool | IsOfType () const |

| ImplType * | Impl () const |

| template<typename T > | |

| T * | Impl () const |

| Reserved for internal use. | |

| bool | operator== (const MTKBase_Feature &theObject) const |

| bool | operator!= (const MTKBase_Feature &theObject) const |

Static Public Member Functions | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returns true if theFeature is a small length flange issue. | |

Static Public Member Functions inherited from cadex::DFMSheetMetal_BendIssue Static Public Member Functions inherited from cadex::DFMSheetMetal_BendIssue | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returns true if theFeature is a DFM sheet metal bend issue. | |

Static Public Member Functions inherited from cadex::DFMBase_Issue Static Public Member Functions inherited from cadex::DFMBase_Issue | |

| static bool | CompareType (const MTKBase_Feature &theFeature) |

| Returnstrue if theFeature is a DFM issue. | |

Additional Inherited Members | |

Public Types inherited from cadex::DFMSheetMetal_BendIssue Public Types inherited from cadex::DFMSheetMetal_BendIssue | |

| typedef cadex::internal::DFMSheetMetalImpl_BendIssue | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Public Types inherited from cadex::DFMBase_Issue Public Types inherited from cadex::DFMBase_Issue | |

| typedef cadex::internal::DFMBaseImpl_Issue | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Public Types inherited from cadex::MTKBase_Feature Public Types inherited from cadex::MTKBase_Feature | |

| typedef cadex::internal::MTKBaseImpl_Feature | ImplType |

| typedef std::shared_ptr< ImplType > | ImplPtrType |

Protected Member Functions inherited from cadex::DFMSheetMetal_BendIssue Protected Member Functions inherited from cadex::DFMSheetMetal_BendIssue | |

| DFMSheetMetal_BendIssue (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Member Functions inherited from cadex::DFMBase_Issue Protected Member Functions inherited from cadex::DFMBase_Issue | |

| DFMBase_Issue (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Member Functions inherited from cadex::MTKBase_Feature Protected Member Functions inherited from cadex::MTKBase_Feature | |

| MTKBase_Feature (ImplPtrType theImpl) | |

| Reserved for internal use. | |

Protected Attributes inherited from cadex::MTKBase_Feature Protected Attributes inherited from cadex::MTKBase_Feature | |

| ImplPtrType | myImpl |

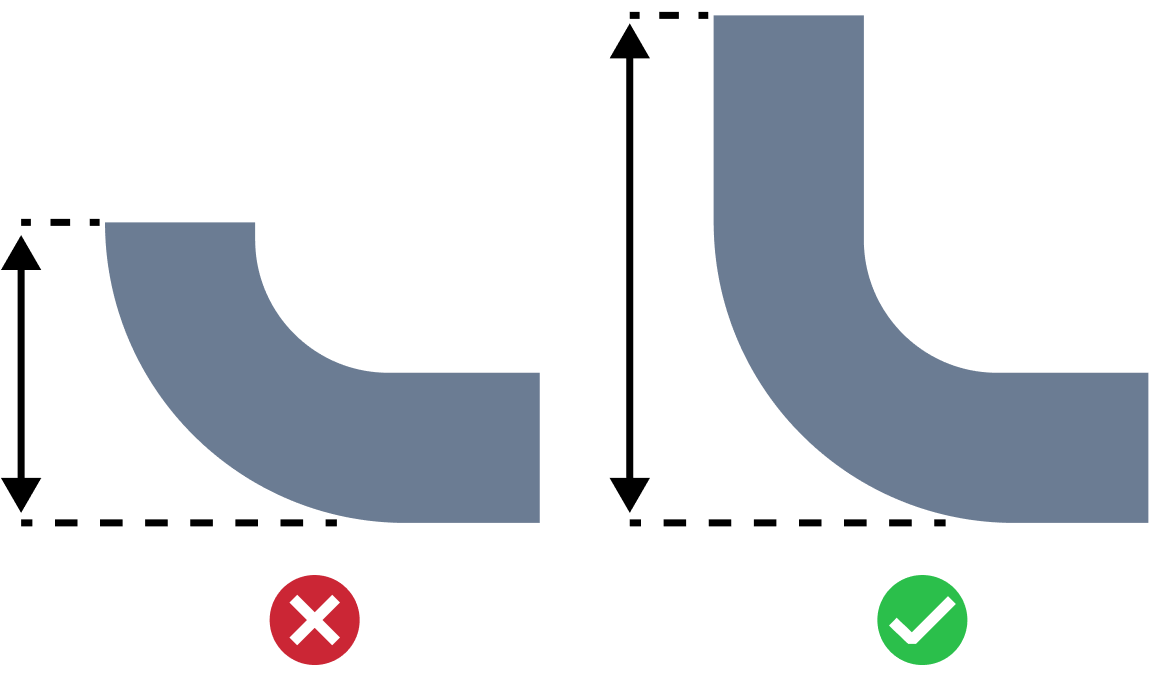

Describes small length flange issues found during sheet metal design analysis.

The flange length refers to the length of the flat section of a flanged edge. A small flange length issue can occur when the flange length is too small to accommodate the intended bend radius. This can cause the material to wrinkle or crack during the forming process, leading to a defective or unusable part.

Contains simple bend and it's flange that fails the following condition:

\[ \large L_f \geq T \times Rt + R_b \]

\[ \begin{aligned} & \small L_f - \text{actual flange length} \\ & \small T - \text{actual sheet thickness} \\ & \small Rt - \text{expected minimum flange length to sheet thickness ratio} \\ & \small R_b - \text{actual bend radius} \end{aligned} \]

| cadex::DFMSheetMetal_SmallLengthFlangeIssue::DFMSheetMetal_SmallLengthFlangeIssue | ( | ) |

Constructor.

| cadex::DFMSheetMetal_SmallLengthFlangeIssue::DFMSheetMetal_SmallLengthFlangeIssue | ( | const MTKBase_CompositeFeature & | theFlange | ) |

Constructor.

Creates a small length flange issue from the MTKBase_CompositeFeature object. The first feature in MTKBase_CompositeFeature should be the flange bend (SheetMetal_Bend) and the second is an end flage face (ModelData::Face) as MTKBase_ShapeFeature object.

| double cadex::DFMSheetMetal_SmallLengthFlangeIssue::ActualLength | ( | ) | const |

Returns the actual flange length in mm .

|

static |

Returns true if theFeature is a small length flange issue.

| double cadex::DFMSheetMetal_SmallLengthFlangeIssue::ExpectedMinLength | ( | ) | const |

Returns the expected minimum flange length in mm .

| double cadex::DFMSheetMetal_SmallLengthFlangeIssue::ExpectedMinLengthToSheetThicknessRatio | ( | ) | const |

Returns the expected minimum flange length to thickness ratio.

\[ \large L_e = T \times Rt + R_b \]

\[ \begin{aligned} & \small L_e - \text{expected minimum flange length} \\ & \small T - \text{actual sheet thickness} \\ & \small Rt - \text{expected minimum flange length to sheet thickness ratio} \\ & \small R_b - \text{actual bend radius} \end{aligned} \]

| const MTKBase_CompositeFeature & cadex::DFMSheetMetal_SmallLengthFlangeIssue::Flange | ( | ) | const |

Returns the problematic flange.

The first feature in MTKBase_CompositeFeature is a flange bend (SheetMetal_Bend) and the second is an end flage face (ModelData::Face) as MTKBase_ShapeFeature object.

| void cadex::DFMSheetMetal_SmallLengthFlangeIssue::SetActualLength | ( | double | theLength | ) | const |

| void cadex::DFMSheetMetal_SmallLengthFlangeIssue::SetExpectedMinLengthToSheetThicknessRatio | ( | double | theRatio | ) |

Sets the expected minimum flange length to thickness ratio.

theRatio should be greater than zero.

| void cadex::DFMSheetMetal_SmallLengthFlangeIssue::SetFlange | ( | const MTKBase_CompositeFeature & | theFlange | ) |

Sets the problematic flange The first feature in MTKBase_CompositeFeature should be the flange bend (SheetMetal_Bend) and the second is an end flage face (ModelData::Face) as MTKBase_ShapeFeature object.